Smart Civil Explosive Solutions

Industry Pain Point

Industry pain points

Plan Objectives

The smart civil explosive information solution aims to achieve intelligent control of the whole process of civil explosive through advanced technical means, improve the essential safety level of the industry, and promote the digital transformation and high-quality development of the civil explosive industry.

Scheme Architecture

Product Architecture

Core Functional System

Core functional system

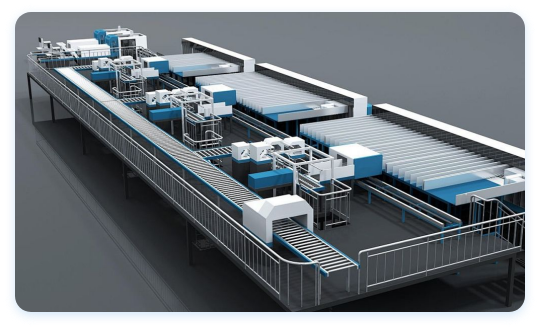

Galileo 3D Digital Factory

Manufacturing Execution System

Raw Material Management

Online Sales Portal System

Intelligent Warehouse Management

Safety Transportation Management

Personnel Safety Management

Energy Management

BI Data Big Screen

Galileo 3D Digital Factory

The core application of "Galileo Smart Factory", "Galileo 3D Digital Factory" will integrate various business systems to facilitate management to unified view the real-time operation of the factory and rapid decision management.

Program Highlights

Highlights of the plan

Program Effectiveness

Plan effectiveness

Digital industry, the trend of the times

Our Customers

Our customers

National High-tech Enterprise

Sichuan High tech Enterprise

"Galileo Platform"Rapid Deployment

Implementation Team one-on-one

National Industrial Internet

Alliance Working Group Core unit

200+Intellectual Property

10Year IoT Technology Accumulation

200+Industrial Cooperation Cases

3000K Access Equipment

- Popular Solutions

- Star Products

- News

- Contact Way

- Manager Zheng:(+86)13678077511