Quality Management System

Starting From Product Quality

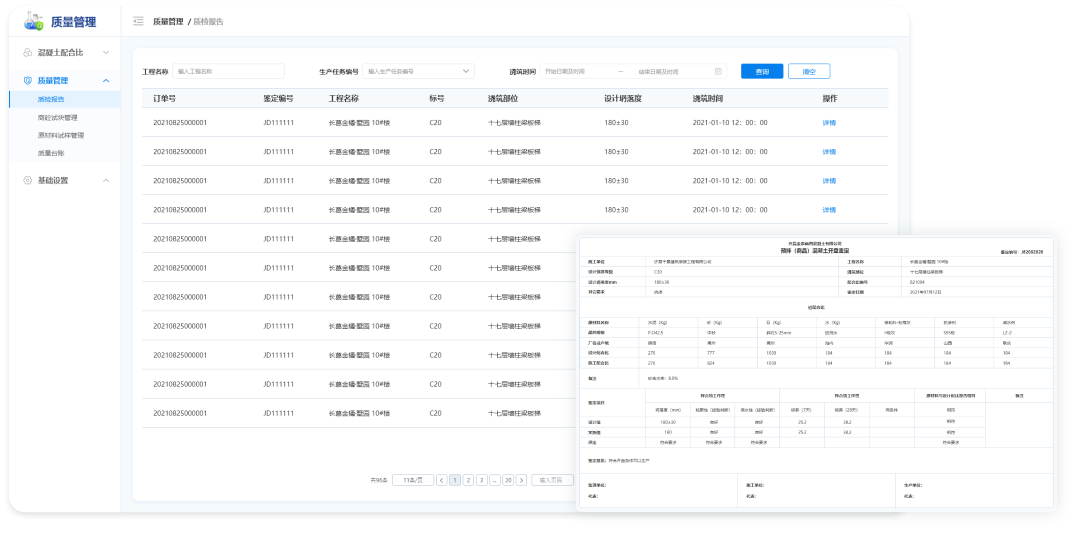

Systematic Introduction

The quality management system is a total quality management solution for enterprises, covering the full life cycle from raw material procurement to product delivery. It realizes quality data collection, analysis, traceability and early warning, and can seamlessly integrate with ERP, MES and supply chain management systems for collaborative optimization. Using it helps enterprises improve product quality, reduce costs and enhance market competitiveness.

System Function

Product Architecture

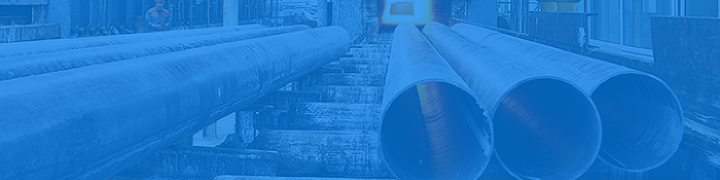

Quality Ledger Management

Establish a quality ledger from raw materials to finished products

Record the purchase and inspection information of raw materials

Quality inspection results of key processes of semi-finished products

Finished product factory inspection and certification information

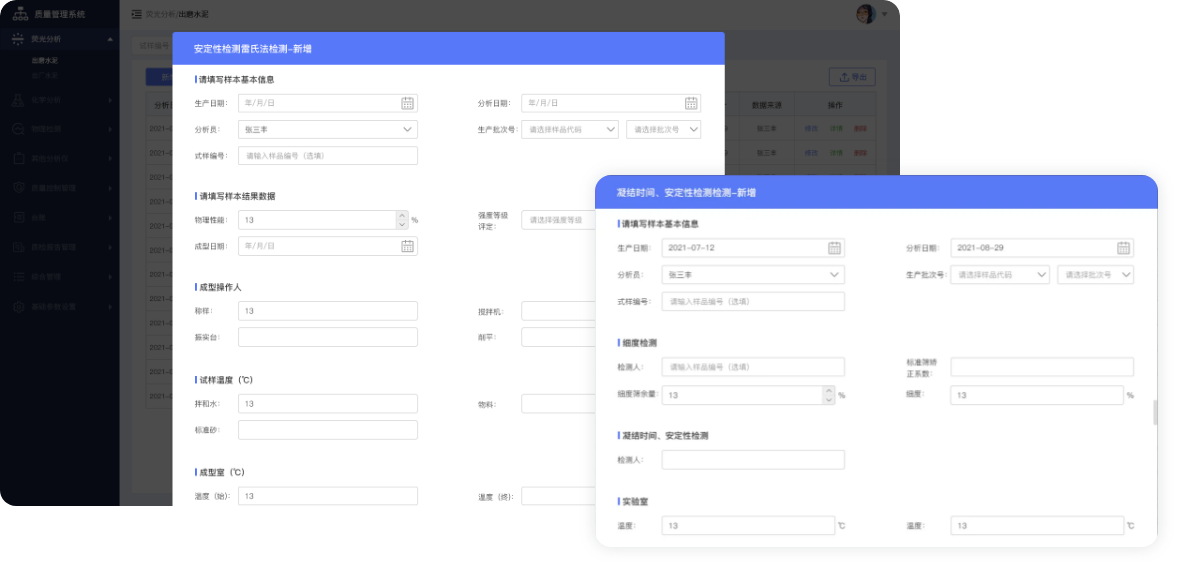

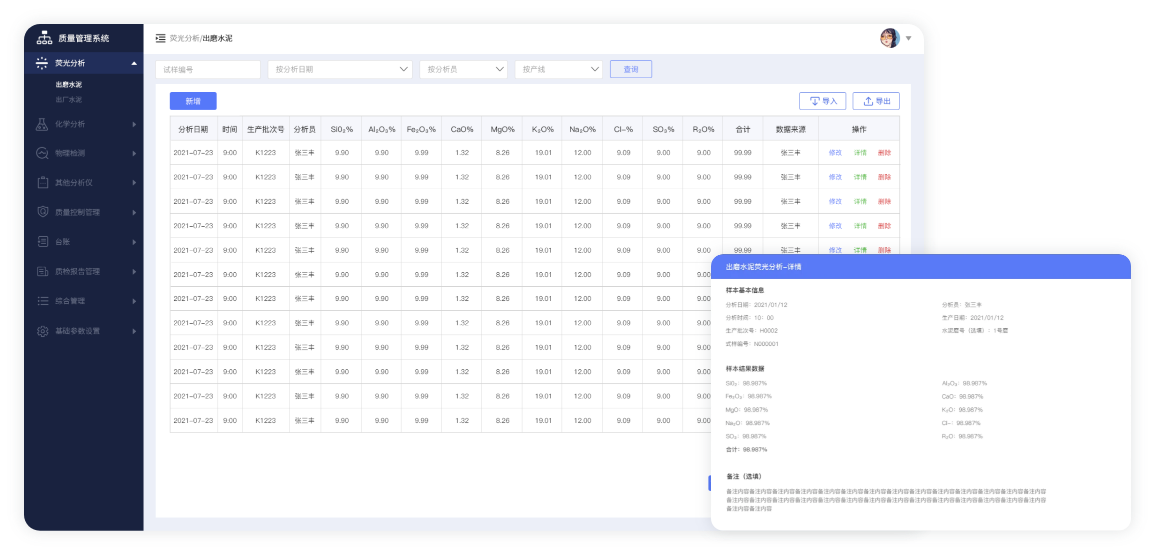

Quality Data Acquisition

Manual Entry

Auto Collection

Batch Import

Ensure data integrity and accuracy

Quality Inspection and Analysis

Provide perfect quality inspection and statistical analysis tools

SPC

MSA

FMEA

Help enterprises to identify quality problems and optimize the production process

Quality Traceability and Early Warning

Establish a quality traceability chain from raw materials to finished products

To achieve rapid positioning of the source of the problem

Set quality early warning rules

Timely detection and disposal of potential quality risks

Production Ratio Management

Data management of laboratory incoming testing, formulation, inspection and other series of work

Improve the convenience and efficiency of work

Intelligent Reporting

Through the experimental data of the date, month, year and different batches of semi-finished products recorded by the system ( analysis group, physical inspection group, control group, central laboratory ), the system can customize the output table to meet the needs of different parts.

System Advantage

System advantages

All-round

Cover the whole life cycle quality management from raw materials to finished products, and realizes the comprehensive coverage and seamless connection of quality management.

Intelligent

Using big data analysis and intelligent algorithms, early warning and automatic diagnosis of quality problems are realized, and the intelligent level of quality management is improved.

Synergistic

Be deeply integrated with ERP, MES and other systems to realize the collaborative optimization of quality management and production operation, and improve the operation efficiency of enterprises.

High Efficiency

Automatic data acquisition and analysis, reduce the workload of manual input and calculation, improve the efficiency of quality management.

Application Scene

Application scenarios

Cement Industry

The quality management of raw materials, semi-finished products and finished products in the cement production process is realized, and the quality traceability system from raw materials to clinker / cement is established. Through the experimental data of different batches of semi-finished products and finished products recorded by the system, the quality report is customized to meet the quality management needs of different departments.

Commercial Concrete Industry

The quality management of the raw materials, formula, production and factory of the commercial mixing station is carried out to ensure the quality stability of the commercial concrete. Through the systematic recording and analysis of the quality data of the commercial mixing station, the ratio design is optimized, and the production efficiency and product quality are improved.

Iron and Steel Industry

The quality of raw materials, molten iron, molten steel and finished products in the iron and steel production process is managed to ensure that the product quality is stable and controllable. Through the systematic recording and analysis of the quality data of key processes such as smelting and rolling, the production parameters are optimized and the product qualification rate is improved.

Lithium Salt Industry

The quality of raw materials, intermediate products and finished products in the production process of lithium salt is managed, and a comprehensive quality traceability system is established. By systematically recording and analyzing the key quality indicators of lithium salt products, the production process is optimized, and the purity and yield of products are improved.

Many companies choose us, with the strength to complete the customer entrustment.

National High-tech Enterprise

Sichuan High tech Enterprise

"Galileo Platform"Rapid Deployment

Implementation Team one-on-one

National Industrial Internet

Alliance Working Group Core unit

200+Intellectual Property

10Year IoT Technology Accumulation

200+Industrial Cooperation Cases

3000K Access Equipment

- Popular Solutions

Smart Cement Building Materials Solutions

Smart Lithium Salt Solutions

Kitchen Waste and Transportation Solutions

Chemical Industry Solutions

Civil Explosion Solutions

Smart Business Concrete Solutions

Aluminum Industry Solutions

Energy Saving and Environmental Protection Solutions

Smart Radio and Television Solutions

Industrial Data Acquisition Solutions

- Star Products

Large-Sized Model of Enterprise Knowledge Base

Environmental Management System

Enterprise Asset Management System

Manufacturing Execution System

Safety Management System

IAP Capacity Expert System

Raw Material Management System

Warehouse Management System

Logistics Tracking System

Slope Monitoring System

- News

- Contact Way

- Manager Zheng:(+86)13678077511

Mobile Phone Consultation

Contact Mail

waynezheng@idmakers.cn

zhuxianjuan@idmakers.cn

Company Address

No.1502, Block B, Triumph South City, No.401 Sheng 'an Street, High-tech Zone, Chengdu City, Sichuan Province, China

Office Location

Chengdu | Lhasa | Urumqi | Chongqing | Paris

Copyright ©2013-PRESENT IDMakers Interactive Co., Ltd. All Rights Reserved. | Shu ICP No.15031909-1