Industrial Large Model Application Solution

The industrial knowledge base big model solution is an intelligent platform tailored for the industrial field. It uses advanced natural language processing and knowledge graph technology to transform massive industrial data, documents and expert experience into a structured knowledge base, and provides a full range of intelligent application support for enterprises through intelligent question answering, knowledge reasoning and decision optimization. Whether it is equipment fault diagnosis, production scheduling optimization, quality inspection and predictive maintenance, our solutions can provide accurate and efficient services to help industrial enterprises achieve digital transformation and intelligent upgrading.

Consult nowIndustry Pain Point

Industry pain points

Industrial enterprises from the traditional experience-driven to data and knowledge driven, through the knowledge base large model to achieve intelligent change.

Data Fragmentation

Industrial data is scattered in various systems and departments, and it is difficult to form a complete digital asset because of the lack of effective integration.

Knowledge fault

Knowledge in key areas is highly dependent on senior experts, but expert experience is difficult to pass on, and staff turnover may lead to the loss of core knowledge.

Lack of Intelligence

Production operations lack intelligent insight and decision support, and it is difficult to achieve real-time optimization and predictive maintenance.

Inefficient Service

Customer service depends on labor, slow response, high cost, difficult to meet customer needs.

Plan Objectives

Industrial large model solutions through AI technology and massive data, build enterprise knowledge base, combined with digital employees to enable production and operation optimization, comprehensively improve the efficiency of manufacturing enterprises, leading the industry intelligent manufacturing and high-quality development.

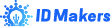

Scheme Architecture

Product Architecture

Program Highlights

Highlights of the plan

Global Knowledge Fusion

Open up the data island, realize the comprehensive integration and sharing of internal and external knowledge, and improve the utilization rate of knowledge assets.

Digital Inheritance of Knowledge

The tacit knowledge such as expert experience is transformed into explicit and structured knowledge to realize long-term preservation and inheritance of knowledge.

Real-time Update

Continuously update the knowledge base to ensure that all decisions and actions are based on the latest data and analysis.

Efficient Customer Service

Intelligent customer service driven by knowledge base significantly improves service efficiency and customer satisfaction.

Flexible and Scalable

It adopts microservice architecture and containerized beasts to support flexible functional expansion and integration to meet the personalized needs of enterprises.

Customizability

The solution is highly customizable and can be adjusted and optimized according to specific industrial scenarios and enterprise needs.

Application Scenario

Application scenarios

Application Cases

Application cases

A Manufacturing Enterprise in Tibet

The enterprise adopts the industrial large model knowledge base solution to build an intelligent customer service system, which reduces the labor cost of customer service by 50 % and significantly improves customer satisfaction.

Digital industry, the trend of the times

Our Customers

Our customers

National High-tech Enterprise

Sichuan High tech Enterprise

"Galileo Platform"Rapid Deployment

Implementation Team one-on-one

National Industrial Internet

Alliance Working Group Core unit

200+Intellectual Property

10Year IoT Technology Accumulation

200+Industrial Cooperation Cases

3000K Access Equipment

- Popular Solutions

- Star Products

- News

- Contact Way

- Manager Zheng:(+86)13678077511