Industrial Data Acquisition Application Solutions

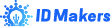

The industrial Internet data acquisition and application solution adopts the ' end-edge-cloud ' architecture, providing full stack capabilities such as device access, edge computing, and cloud services. It supports high concurrent access of massive devices and flexibly adapts to various industrial protocols. The edge side provides data acquisition, cleaning, storage, analysis, control and other nearby calculation and processing. The cloud platform provides PaaS capabilities such as device management, application development, and data services. To realize the whole life cycle management of equipment for industrial customers and help industrial digital transformation.

Consult nowIndustry Pain Point

Industry pain points

The industrial field faces many challenges such as high labor costs, inconsistent data acquisition protocols, high development costs, and lack of flexible deployment at the edge. Integrated solutions are needed to improve data acquisition and processing efficiency, reduce operating costs, and achieve digital transformation.

A Wide Variety of Agreements

Industrial equipment protocol is not uniform, data acquisition and transmission difficulties

Data is Not Interoperable

OT / IT systems are fragmented, and data exchange and sharing are difficult.

Insufficient Edge Calculation

Insufficient edge intelligence, high real-time and reliability requirements

High Cost

Development is difficult, integration and operation and maintenance costs are high

Plan Objectives

The industrial data acquisition solution aims to build a full-process data acquisition system, eliminate information islands, provide complete and high-quality data support for production optimization, quality control, energy efficiency improvement and business decision-making, and enable the digital and intelligent transformation of cement enterprises.

Scheme Architecture

Product Architecture

Program Highlights

Highlights of the plan

Full Stack

Hardware and software integrated delivery, providing connectivity, computing, storage, platform, service full stack capabilities.

High Compatibility

Support 200 + industrial agreement, fast southbound equipment docking, northbound IT system to get through.

Easy Integration

Open rich API, support privatization and custom development, flexible integration of various upper applications.

Operable Maintenance

Provides networking, management, monitoring, and operation and maintenance services to achieve lifecycle management of devices.

Flexible Rules Engine

Flexible rule engine, to achieve free flow of messages, seamless public cloud services, support one-stop data analysis and processing.

Micro-service

The cloud native architecture supports the horizontal expansion of the solution and quickly builds an industrial Internet platform.

Application Scene

Application scenarios

Application Cases

Application cases

A Power Company in Shanxi

The power company uses the industrial data acquisition solution to realize the remote monitoring and management of the power base station, which greatly improves the operation and maintenance efficiency.

Digital industry, the trend of the times

Our Customers

Our customers

National High-tech Enterprise

Sichuan High tech Enterprise

"Galileo Platform"Rapid Deployment

Implementation Team one-on-one

National Industrial Internet

Alliance Working Group Core unit

200+Intellectual Property

10Year IoT Technology Accumulation

200+Industrial Cooperation Cases

3000K Access Equipment

- Popular Solutions

- Star Products

- News

- Contact Way

- Manager Zheng:(+86)13678077511