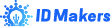

Smart Chemical Solutions

The platform can realize the full-chain visual management of raw materials entering the factory, product production, warehousing and logistics, terminal sales, and market consumption, assist enterprises to quickly establish a traceability system that meets national and market supervision, help enterprises realize the information management of big data ecosystem, and improve the activities and processes of planning, coordination, operation, and optimization of all links of the enterprise supply chain. And can achieve efficient, accurate, flexible strategy analysis and decision-making。

Consult nowPlan Objectives

Fully intelligent and digitized chemical production processes to improve safety, efficiency and environmental compliance, while reducing operating costs and optimizing decision making.

Industry Pain Point

Industry pain points

Underdecision

Management decision-making basis is insufficient, lack of digital production and operation management platform.

Insufficient Production Efficiency

Traditional chemical production equipment and processes are not automated enough, affecting production efficiency.

High Environmental Pressure

In the face of strict environmental regulations, chemical companies need to effectively control emissions.

Data Island Problem

Information silos such as production, warehousing and logistics affect decision-making efficiency.

High Operating Costs

Low resource utilization efficiency and large energy consumption increase the operating costs of enterprises.

High Security Risk

The chemical industry has a high risk of accidents, and the safety management requirements are extremely strict.

Scheme Architecture

Product Architecture

System Function

system function

Real-time Monitoring

Monitor the key variables in the production process to ensure production safety.

Predictive Maintenance

Use data analytics to predict equipment failures and reduce unplanned downtime.

Energy Efficiency Management

Monitor and optimize energy use and reduce energy costs.

Environmental Management

Real-time monitoring of environmental emissions to ensure compliance with relevant environmental standards.

Manufacturing Execution System

Improve the automation and information level of production scheduling.

Logistics and Warehousing Systems

Optimize material flow and inventory management to reduce logistics costs.

Programme Advantages

Advantages of the plan

Improve Security

Reduce safety accidents, protect equipment and personnel safety.

Reinforced Efficiency

Improve production and operation efficiency through automation and informatization.

Reduce Cost

Optimize resource use and energy consumption to reduce overall operating costs.

Compliance with Environmental Standards

Effectively manage and control the environmental impact in the production process.

Improve Data Utilization

Break the information island, through data integration to improve management and decision-making efficiency.

Application Case

Application cases

Hubei Large Chemical Enterprise

A large chemical enterprise in Hubei introduced our intelligent chemical plant information solution. After the deployment, the company 's production efficiency increased by 25 %, equipment maintenance costs decreased by 15 %, and the rate of major safety accidents decreased by 40 %. At the same time, the company 's environmental protection emissions fully met the national standards, which greatly enhanced the company 's market competitiveness and brand image.

Digital industry, the trend of the times

Our Customers

Our customers

National High-tech Enterprise

Sichuan High tech Enterprise

"Galileo Platform"Rapid Deployment

Implementation Team one-on-one

National Industrial Internet

Alliance Working Group Core unit

200+Intellectual Property

10Year IoT Technology Accumulation

200+Industrial Cooperation Cases

3000K Access Equipment

- Popular Solutions

- Star Products

- News

- Contact Way

- Manager Zheng:(+86)13678077511