IAP Capacity Expert System

Intelligent Device Control Experts to Help You Improve Quality and Efficiency

Systematic Introduction

IAP capacity expert system is an intelligent manufacturing solution with the core of improving equipment control and optimization. The system integrates advanced technologies such as industrial big data analysis, mechanism modeling, and expert knowledge base. Through intelligent optimization control of production equipment and processes, the equipment performance is maximized, and the production line production efficiency and product quality are improved. The system can automatically calculate the optimal control parameters of the equipment according to the process requirements and quality objectives, replace manual trial and error, and perform intelligent diagnosis and predictive maintenance of equipment faults. At the same time, the system summarizes the rich experience of engineering experts and forms a knowledge base of equipment control, which can provide intelligent decision support for front-line engineers.

System Function

Product Architecture

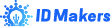

Equipment Control Optimization

Intelligent computing equipment recent control parameters, to achieve optimal equipment performance.

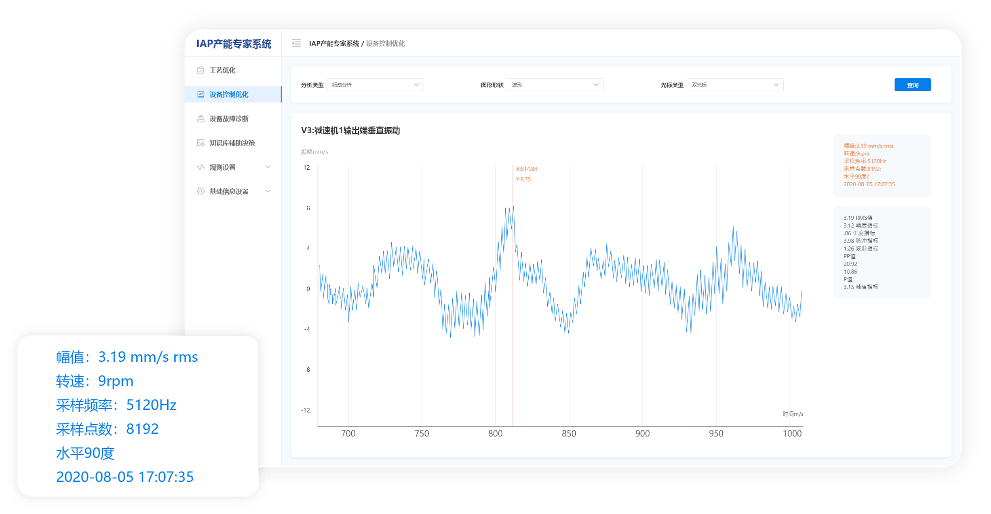

Process Optimization

According to the process requirements and quality objectives, the equipment control is dynamically optimized to improve product quality.

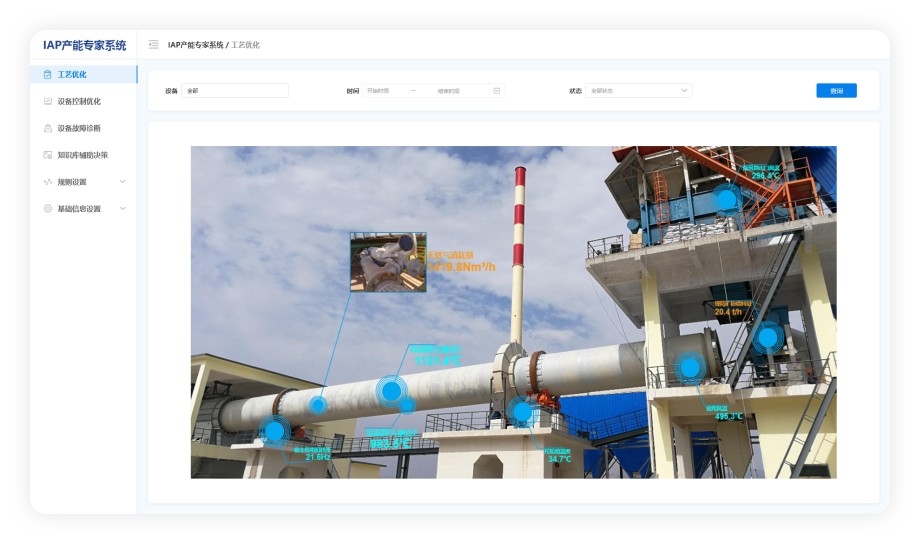

Equipment Fault Diagnosis

Through big data analysis, the cause of equipment failure is accurately diagnosed and the downtime is shortened.

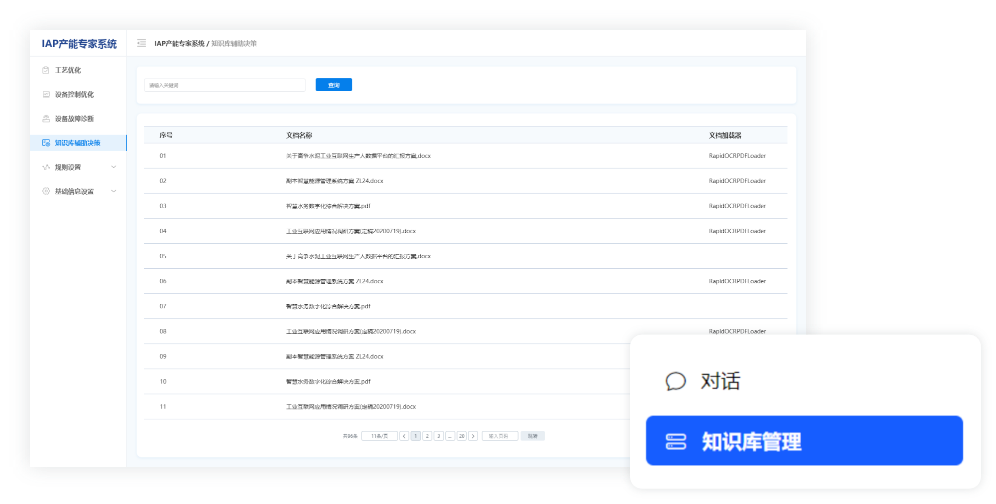

Knowledge Base Aided Decision-making

Summarize the experience of engineering experts, form a knowledge base for equipment control, and assist frontline engineers in making decisions.

System Advantages

System advantages

The IAP production capacity expert system focuses on improving equipment control, the core link of intelligent manufacturing. Through continuous optimization of production equipment control and expert-level auxiliary decision-making, it helps enterprises achieve the goal of ' reducing people, improving quality and increasing efficiency ', and promotes manufacturing to intelligent and lean upgrading.

Expert-level Control

Through intelligent algorithms and expert knowledge, equipment control reaches the expert level.

Rapid Debugging

Automatically calculate the best control parameters, greatly shorten the equipment debugging time, speed up the production of products.

Reduce People Improve Efficiency

Through the intelligent control and decision support of the equipment, the single person control equipment is improved.

Continuous Optimization

Through continuous accumulation and optimization of machine learning, the level of equipment control is continuously improved.

Application Scene

Application scenarios

Discrete Manufacturing

Hardware, electronics, automotive and other industries processing equipment control.

Process Manufacturing Industry

Process control and optimization of cement, lithium salt, petrochemical and other industries.

Equipment Manufacturing Industry

Intelligent control and optimization of high-end equipment such as machine tools and robots.

More Enterprise Scene Trials

Consult Immediately→Many companies choose us, with the strength to complete the customer entrustment.

National High-tech Enterprise

Sichuan High tech Enterprise

"Galileo Platform"Rapid Deployment

Implementation Team one-on-one

National Industrial Internet

Alliance Working Group Core unit

200+Intellectual Property

10Year IoT Technology Accumulation

200+Industrial Cooperation Cases

3000K Access Equipment

- Popular Solutions

Smart Cement Building Materials Solutions

Smart Lithium Salt Solutions

Kitchen Waste and Transportation Solutions

Chemical Industry Solutions

Civil Explosion Solutions

Smart Business Concrete Solutions

Aluminum Industry Solutions

Energy Saving and Environmental Protection Solutions

Smart Radio and Television Solutions

Industrial Data Acquisition Solutions

- Star Products

Large-Sized Model of Enterprise Knowledge Base

Environmental Management System

Enterprise Asset Management System

Manufacturing Execution System

Safety Management System

IAP Capacity Expert System

Raw Material Management System

Warehouse Management System

Logistics Tracking System

Slope Monitoring System

- News

- Contact Way

- Manager Zheng:(+86)13678077511

Mobile Phone Consultation

Contact Mail

waynezheng@idmakers.cn

zhuxianjuan@idmakers.cn

Company Address

No.1502, Block B, Triumph South City, No.401 Sheng 'an Street, High-tech Zone, Chengdu City, Sichuan Province, China

Office Location

Chengdu | Lhasa | Urumqi | Chongqing | Paris

Copyright ©2013-PRESENT IDMakers Interactive Co., Ltd. All Rights Reserved. | Shu ICP No.15031909-1