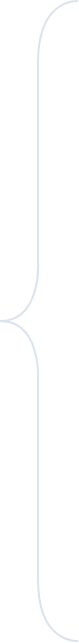

Advanced Process Control (APC) Solution for Spodumene Calcination Rotary Kiln

In a market environment with cyclical lithium price fluctuations, the Spodumene Calcination Rotary Kiln, as the 'heart' of the industry chain, has its operating efficiency and stability directly determining an enterprise's profitability and market competitiveness. This solution will detail how we utilize a new generation of Advanced Process Control technology—fusing Model Predictive Control (MPC), Expert Systems (ES), and Artificial Intelligence Large Models (LM)—to precisely resolve the core operational conflict between 'high conversion rate' and 'ring formation risk.' We will elevate the rotary kiln's operating efficiency to a new height, build a solid and sustainable cost moat for you, help your enterprise navigate the cycles, and achieve operational excellence.

Get a Customized SolutionStrategic Positioning

strategic positioning

Problem Description and Core Pain Points

core pain points

High Conversion Rate vs. Ring Formation Risk

To ensure $\alpha$-$\beta$ phase transition, a high temperature of 1050-1100°C must be maintained, but material tends to melt and form rings, forcing production shutdowns.

Human Operation Bottleneck

Personnel tend towards conservative operation, leading to high energy consumption and low capacity. Inconsistent performance across shifts causes quality fluctuations.

Limitations of Traditional Control

PID cannot handle multivariable strong coupling and long time delay, making precise and stable optimization control difficult.

Raw Material Composition Disturbances

Fluctuations in ore grade, impurities, and moisture content are major unmeasured disturbances, exacerbating operational instability.

Case Study

Analysis

By implementing expert system-based intelligent control, we translated veteran operators' vague judgments (such as 'the fire is too strong') into precise, computer-executable commands, solving the challenges of large clinker quality fluctuations, high energy consumption, and dependence on manual labor.

Solution Upgrade

Plan upgrade

Wider Operating Window

Higher tolerance for parameters like temperature.

Lower Material Value

The value per ton of clinker is relatively limited.

Moderate Quality Requirements

Relatively relaxed control requirements for final product quality.

"Post-Facto Reactive" Control

Feedback control based on issues is generally sufficient.

Extremely Narrow Operating Window

Calcination temperature must be precisely controlled within 1050-1100°C.

Extremely High Material Value

Lithium-containing minerals are highly valuable; any loss is costly.

Strict Quality Requirements

Beta-phase conversion rate directly affects final recovery rate, requiring >98%.

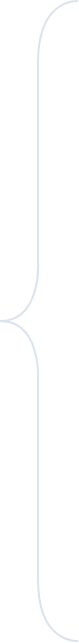

Requires "Forward-Looking" Predictive Control

Must actively predict and avoid risks, rather than passively respond.

Schematic of Process Risks in Spodumene Calcination Rotary Kiln

Operating Temperature Window

The narrow process operating window increases control difficulty

Temperature Too Low

Ideal Balance Point

Temperature Too High

The Way to Break the Impasse

Solution to Break the Deadlock

Three-Layer Hybrid Intelligent Architecture

Pure Expert Systems or MPC are insufficient to meet the stringent challenges of the lithium salt industry. We propose a new intelligent architecture that deeply integrates algorithms, data, and expert knowledge to achieve a synergistic effect where 1+1+1 > 3.

As the core engine of the system, it is responsible for continuous, real-time online optimization. It uses dynamic mathematical models to 'predict' the future and calculates the optimal sequence of operations that achieves economic objectives (lowest energy consumption, highest output) while satisfying all safety and process constraints.

Handle Multivariable Coupling

Inherently describe the mutual influence of each input on all outputs, enabling global coordinated control.

Compensate for Long Time Delays

"Foresight" and compensate for the time delay caused by material transport, enabling proactive control.

Strict Constraint Handling

Push the process to operate at the edge of safety constraints, unearthing hidden production potential.

System Architecture

Product Architecture

System Integration Overview

Core Key Functions

Core key functions

Global control based on a defined variable matrix (CVs, MVs, DVs) and a multi-objective optimization function guided by economic benefits, quality, and safety.

Creating Quantifiable Value for Your Enterprise

quantifiable value

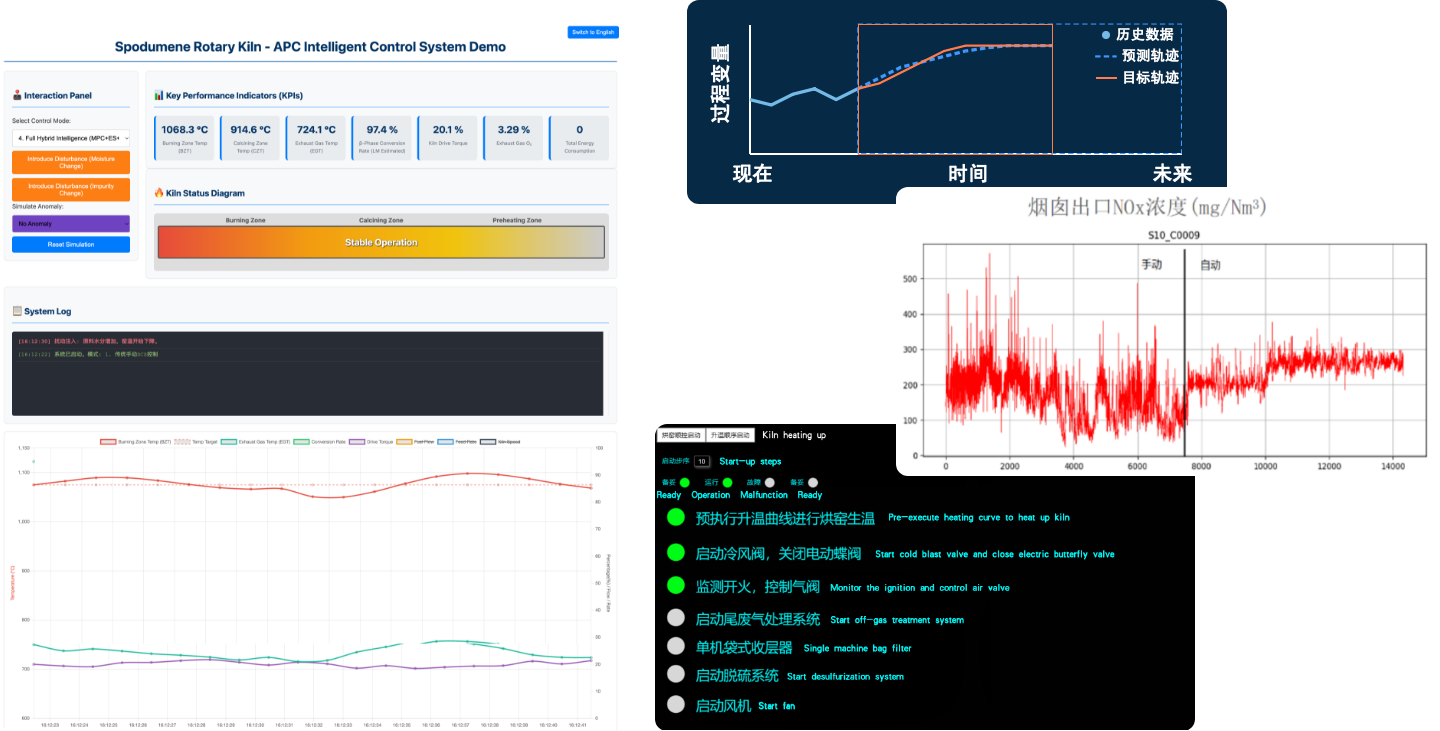

Process Stability Improvement

Key parameter standard deviation reduced by 50%-70%, significantly reducing process fluctuations and laying the foundation for high-quality production.

Overall Energy Consumption/Cost Reduction

Unit product energy consumption reduced by 5%-15%, directly saving costs on steam, electricity, etc., and increasing profit margin.

Product Yield/Capacity Increase

Core product yield increased by 2%-5%, key product conversion rate stabilized above 98%, maximizing plant output.

Operational Automation Rate Increase

Manual intervention in key loops reduced by >80%, formalizing expert experience, achieving "black screen operation," and minimizing human error.

Our Core Strengths

quantifiable value

Leading MPC Algorithm

Adopt industry-leading multivariable predictive control algorithms to accurately handle strong coupling and large time-delay issues, ensuring optimal control effectiveness.

Integration of Top Process Knowledge

Strong collaboration with top institutions like Carson Design Institute to integrate the invaluable experience of expert kiln operators into the system, achieving a perfect fusion of intelligence and process expertise.

Industry-Focused Team

Our team consists not only of control experts but also senior engineers with a profound understanding of your industry's process, ensuring the solution is highly aligned with actual operating conditions from the source.

Flexible Customization and Integration

The platform possesses high flexibility and openness, allowing for functional customization according to your specific needs and seamless integration with existing DCS, MES, and other systems.

Expected Outcomes and Core Advantages

core advantages

Proactive Predictive Control

The operating mode is upgraded from passive feedback to active prediction, with the system automatically performing global optimization for more stable operation.

Significant Risk Reduction

Intelligent early warning predicts anomalies like ring formation in advance, transforming post-event handling into proactive prevention, ensuring production continuity.

Operator Role Elevation

Operators shift from executors to supervisors, reducing human fluctuations, eliminating shift-to-shift differences, and enhancing human efficiency.

Technological Synergy Advantage

MPC, ES, and LM complement each other, forming a synergistic effect of 1+1+1>3, making the system more resilient and adaptable.

Knowledge Transfer and Formalization

Convert senior expert experience into enterprise digital assets, solving the risk of knowledge loss and formalizing core technological competitiveness.

Quantifiable Economic Benefits

Ensure a substantial return on project investment in the short term by increasing conversion rate, reducing energy consumption, and boosting capacity.

Professional, Rigorous Implementation Process

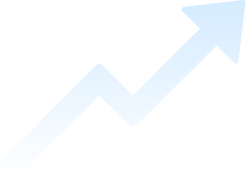

Implementation Process

Project Kick-off and Survey

Form a project team, conduct in-depth on-site surveys, and clarify control objectives and expected benefits.

Data Collection and Testing

Design and execute step tests, collecting high-quality process data for model identification.

Model Identification and Controller Design

Establish a high-precision process model, design and perform offline simulation of the APC controller.

Online Commissioning and Optimization

Put the controller into online operation, and perform parameter tuning and performance optimization based on actual results.

Benefit Evaluation and Acceptance

Quantify the various benefits brought by the system after commissioning, conduct project acceptance and knowledge transfer.

Digital industry, the trend of the times

Our Customers

Our customers

Embark on Your Smart Factory Transformation Journey

Our expert team is ready to provide you with tailor-made solutions. Contact us today for a free consultation and on-site assessment.

Consult Now

National High-tech Enterprise

Sichuan High tech Enterprise

"Galileo Platform"Rapid Deployment

Implementation Team one-on-one

National Industrial Internet

Alliance Working Group Core unit

200+Intellectual Property

10Year IoT Technology Accumulation

200+Industrial Cooperation Cases

3000K Access Equipment

- Popular Solutions

- Star Products

- News

- Contact Way

- Manager Zheng:(+86)13678077511

Ring Formation Risk Zone

Ring Formation Risk Zone